Isostatic Graphite Block for EDM

Basic Info.

| Model NO. | Special graphite block |

| Shore Hardness | 45-75 |

| Application | Sintering Mold ,EDM |

| Ash Content | 300-800ppm |

| Bending Strength | 35-55 MPa |

| Bulk Density | 1.80-1.90 g/cm3 |

| Average Grain Size | 8-25 Micron |

| Transport Package | Wooden Case or as Customer Demand |

| Specification | Dimension as your demand |

| Trademark | xs |

| Origin | China |

| HS Code | 3801100090 |

| Production Capacity | 5000ton/Month |

Product Description

Products Specification :

| Bulk Density | Hardness | Electrical Resistivity | Flexural Strength | Compressive Strength | Tensile Strength | Young's Modulus | Coefficient of Thermal Expansion | Coefficient of Thermal Conductivity | Standard Size |

|---|---|---|---|---|---|---|---|---|---|

| (HSD) | μΩm | MPa | MPa | MPa | GPa | 10-6/K | W/(mK) | (mm) | |

| 1.77 | 51 | 11.0 | 39 | 78 | 25 | 9.8 | 4.5 | 120 | 305×620×1000 410×410×2040 D585×1050 |

| 1.78 | 55 | 12.5 | 39 | 88 | 28 | 10.8 | 4.7 | 100 | 305×620×1000 D585×1050 |

| 1.90 | 60 | 9.5 | 54 | 103 | 29 | 11.8 | 4.8 | 140 | 230×620×1000 |

| 1.75 | 60 | 17.0 | 38 | 88 | 25 | 9.5 | 4.6 | 80 | D585×1050 305x620x1000 |

| 1.82 | 55 | 9.2 | 54 | 90 | 37 | 10.8 | 4.8 | 140 | 300× 540× 850 |

| 1.88 | 55 | 9.0 | 60 | 110 | 40 | 12.0 | 4.9 | 140 | 300×540×850 |

| 1.77 | 57 | 12.2 | 43 | 88 | 27 | 10.3 | 4.7 | 100 | 190×620×1500 D1150×560 |

| 1.83 | 58 | 10.0 | 47 | 103 | 31 | 11.8 | 4.6 | 130 | 305×620×1000 D460×1050 |

| 1.68 | 45 | 13.5 | 36 | 69 | 20 | 8.8 | 4.2 | 90 | 305×620×1000 |

| 1.78 | 55 | 11.0 | 41 | 83 | 25 | 9.8 | 4.6 | 120 | 305×620×1000 |

| 1.85 | 60 | 10.0 | 49 | 103 | 29 | 11.8 | 5.0 | 130 | 305×620×1000 |

| 1.78 | 63 | 13.4 | 52 | 106 | 34 | 10.1 | 5.6 | 90 | 305×620×1050~1200 |

| 1.78 | 76 | 15.0 | 65 | 135 | 46 | 12.0 | 5.6 | 70 | 230×540×1000 |

| 1.82 | 75 | 14.4 | 70 | 134 | 46 | 12.6 | 7.1 | 80 | 180×450×850 |

| 1.82 | 80 | 15.5 | 76 | 172 | 54 | 13.2 | 5.6 | 70 | 230×540×1000 |

| 1.80 | 70 | 13.0 | 60 | 130 | 40 | 11.5 | 5.1 | 100 | 305×620×1000 230×540×1000 |

| 1.78 | 72 | 14.0 | 73 | 135 | 49 | 10.9 | 5.0 | 90 | 210×510×950 |

| 1.78 | 80 | 15.5 | 80 | 150 | 53 | 11.6 | 5.7 | 80 | 210×510×950 |

| 1.77 | 78 | 15.0 | 80 | 155 | 55 | 12.0 | 5.3 | 80 | 150×400×700 |

| 1.77 | 90 | 18.0 | 92 | 180 | 67 | 13.0 | 5.8 | 70 | 150×400×700 |

| 1.85 | 60 | 10.0 | 49 | 103 | 29 | 11.8 | 5.0 | 130 | 305×620×1000 |

| 1.77 | 65 | 14.1 | 47 | 93 | 29 | 10.8 | 5.0 | 80 | 305×620×1000 |

| 1.78 | 73 | 14.3 | 75 | 140 | 50 | 11.0 | 5.1 | 90 | 210×510×950 |

| 1.78 | 81 | 15.7 | 80 | 156 | 55 | 11.8 | 5.8 | 80 | 210×510×950 |

| 1.91 | 88 | 13.5 | 100 | 210 | 74 | 12.7 | 5.7 | 95 | 100×500×950 |

| 1.77 | 80 | 15.1 | 83 | 161 | 58 | 12.2 | 5.2 | 80 | 150×400×700 |

| 1.77 | 92 | 18.2 | 96 | 187 | 70 | 13.3 | 5.9 | 70 | 150×400×700 |

1. The figures above are typical values, and are not guaranteed.

2. The measurement temperature range for the coefficient of thermal expansion is 350 to 450ºC.

3. There are other product sizes in addition to those described above. Contact us for details.

Products details

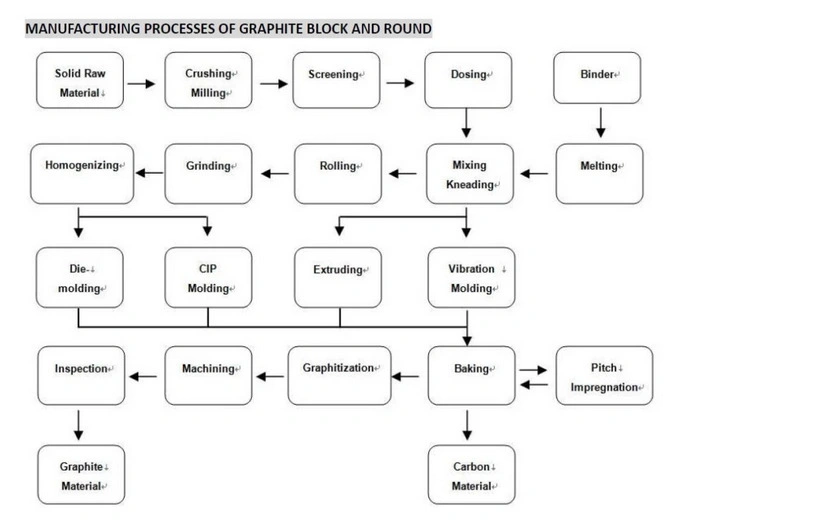

Formed by means of CIP (cold isostatic pressing) technique, isostatic graphite is characterized by its homogeneous structure and excellent isotropic electrical, thermal and mechanical properties. Sometimes it is purified in special-designed graphitization furnace to remove non-carbonaceous impurities. It is widely used in a variety of industrial and scientific engineering as a structural and/or functional material.Applications

Molds in continuous casting systems for making shaped steel, cast iron, copperSintering molds for cemented carbides, diamond tools and electronic componentsMolds for making shaped glassCrucibles for melting precious metals or alloysElectrodes for EDMHeating elements, heat shields, crucibles, boats in furnaces for pulling monocrystalline silicon or optical fibersAnodes for production of manganese dioxide, metallic magnesium & rare metals and etc.

Programmable properties

Fine grainHomogeneous structureIsotropic propertiesHigh density and high mechanical strengthHigh thermal and chemical resistanceHigh resistance to thermal shockProper electrical conductivityHigh oxidation resistanceLow ash